Tofino Coastal Passive House

Tofino, BC

This one was tricky from day one. The clients wanted oceanfront living but weren't about to compromise on energy efficiency. We're talking full passive house certification on a site that gets hammered by Pacific storms. Yeah, not your typical weekend project.

Project Timeline

Phase 1: Initial Consultation (March 2021)

Met the Hendersons at their cramped rental near the beach. They'd been dreaming about this for years - a home that'd work with the environment instead of fighting it. We spent hours just walking the site, feeling how the wind moved, where the sun hit. That's when we knew the house had to nestle into the slope rather than sit on top of it.

Before: Raw coastal site with amazing potential

Phase 2: Design Development (May-Sept 2021)

Here's where things got interesting. Passive house standards are brutal - there's zero room for error on thermal bridging. We went through probably fifteen iterations of the window placement alone. The structural engineer thought we were nuts trying to cantilever the upper floor over the living space, but that's what gave us those killer ocean views without destroying the heat envelope.

Technical drawings showing thermal envelope details

Early rendering - pretty close to what we actually built

Phase 3: The Build (March 2022-Aug 2023)

Not gonna lie, this was tough. Weather delays, supply chain issues with the triple-pane windows from Europe, and one particularly memorable incident where we had to re-do an entire wall section because the blower door test showed we had air leakage. The crew was phenomenal though - everyone bought into the vision and really pushed to get the details right. The airtightness testing came in at 0.45 ACH50, which is insane for a coastal build.

Framing stage - that's where precision matters

Our crew working on exterior cladding

Installing the high-performance insulation system

Final Result (September 2023)

The Hendersons moved in during a typical wet fall week, and their heating system barely kicked on. We're talking outdoor temps in the single digits, and the house stayed comfortable with minimal energy input. That's what proper passive design gets you. Plus, they can actually hear themselves think now - the acoustic performance from all that insulation is a bonus they didn't expect.

Living space with those ocean views we fought for

Exterior blending into the landscape

"We'd worked with another architect before who just didn't get what we were trying to do. Onyx Thor Valquint actually listened. Yeah, the process took longer than we expected, but they never cut corners. Our energy bills are basically non-existent now, and the house feels alive - if that makes sense. It breathes with the seasons. Worth every penny and every headache along the way."

- Sarah & Michael Henderson, Homeowners

Technical Highlights

2,850

Square Feet

0.45

ACH50 (Airtightness)

89%

Energy Reduction vs Code

$2.4M

Total Project Cost

Gastown Heritage Adaptive Reuse

Vancouver, BC

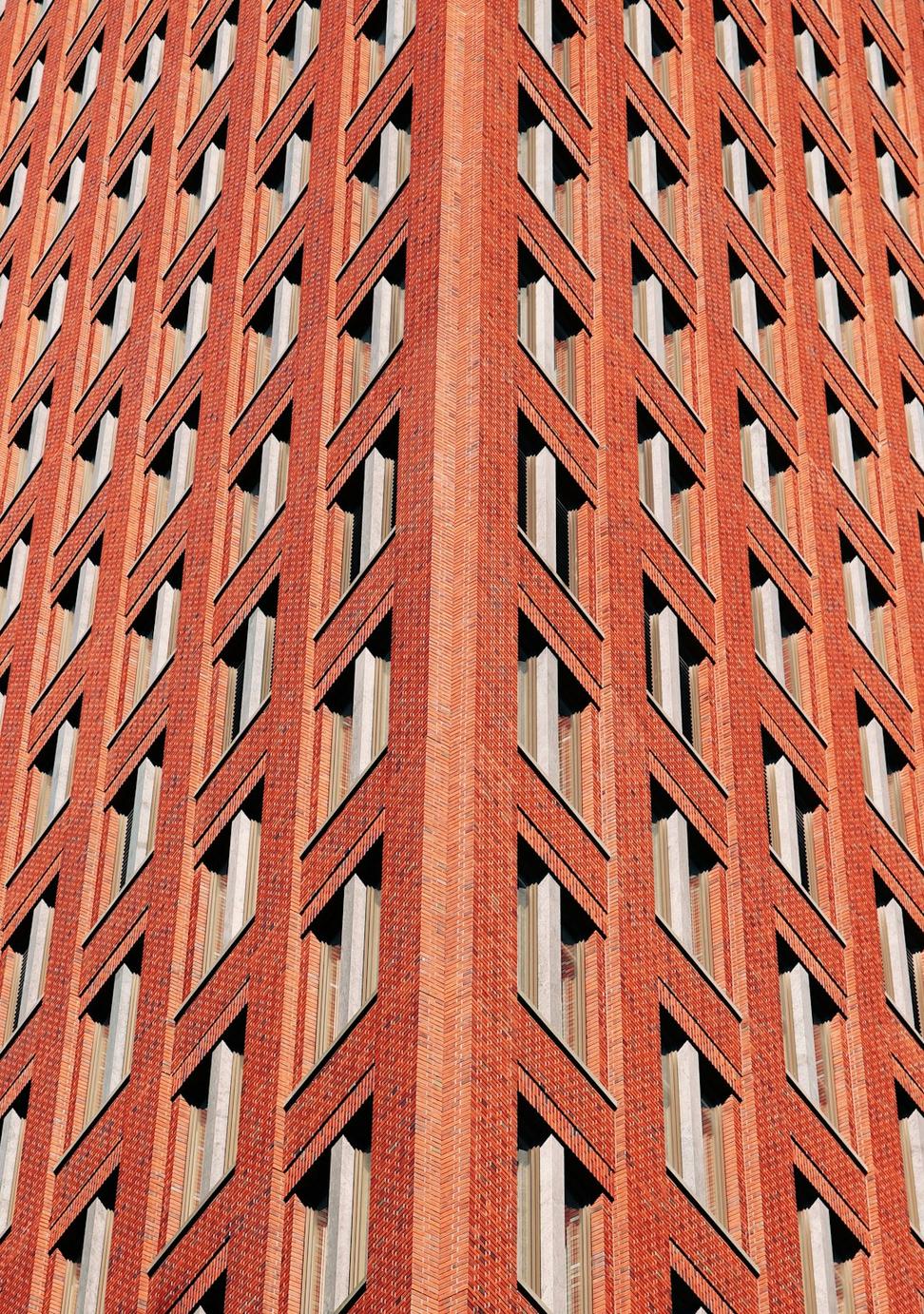

Taking a 1912 warehouse and turning it into modern mixed-use space without losing its soul - that's what this project was all about. The city's heritage committee had strong opinions (as they should), and we had to balance their requirements with what actually makes financial sense for the developer.

Development Story

Discovery (January 2020)

The building had been sitting empty for almost a decade. Water damage, structural issues, the works. But man, those original timber beams and that brick facade - you don't see craftsmanship like that anymore. We convinced the developer to keep as much original material as possible, which meant a lot more work but way better end result.

Original state - decades of neglect but good bones

Those original beams were worth saving

Heritage Approval Process (March-Nov 2020)

Eight months of back-and-forth with the heritage committee. Every detail scrutinized - window profiles, brick repair methods, even the color of the mortar. Frustrating? Sure. But they were protecting something important. We ended up learning a ton about traditional building methods that we wouldn't have otherwise.

Renovation & Construction (Jan 2021-Sept 2023)

The structural engineer earned every penny on this one. We had to basically build a new building inside the old shell while keeping everything plumb and true. Added a whole new floor on top using steel framing that distributed loads to the reinforced original columns. The mechanical systems were a puzzle - trying to hide ductwork in a heritage building isn't for the faint of heart.

Structural work in progress

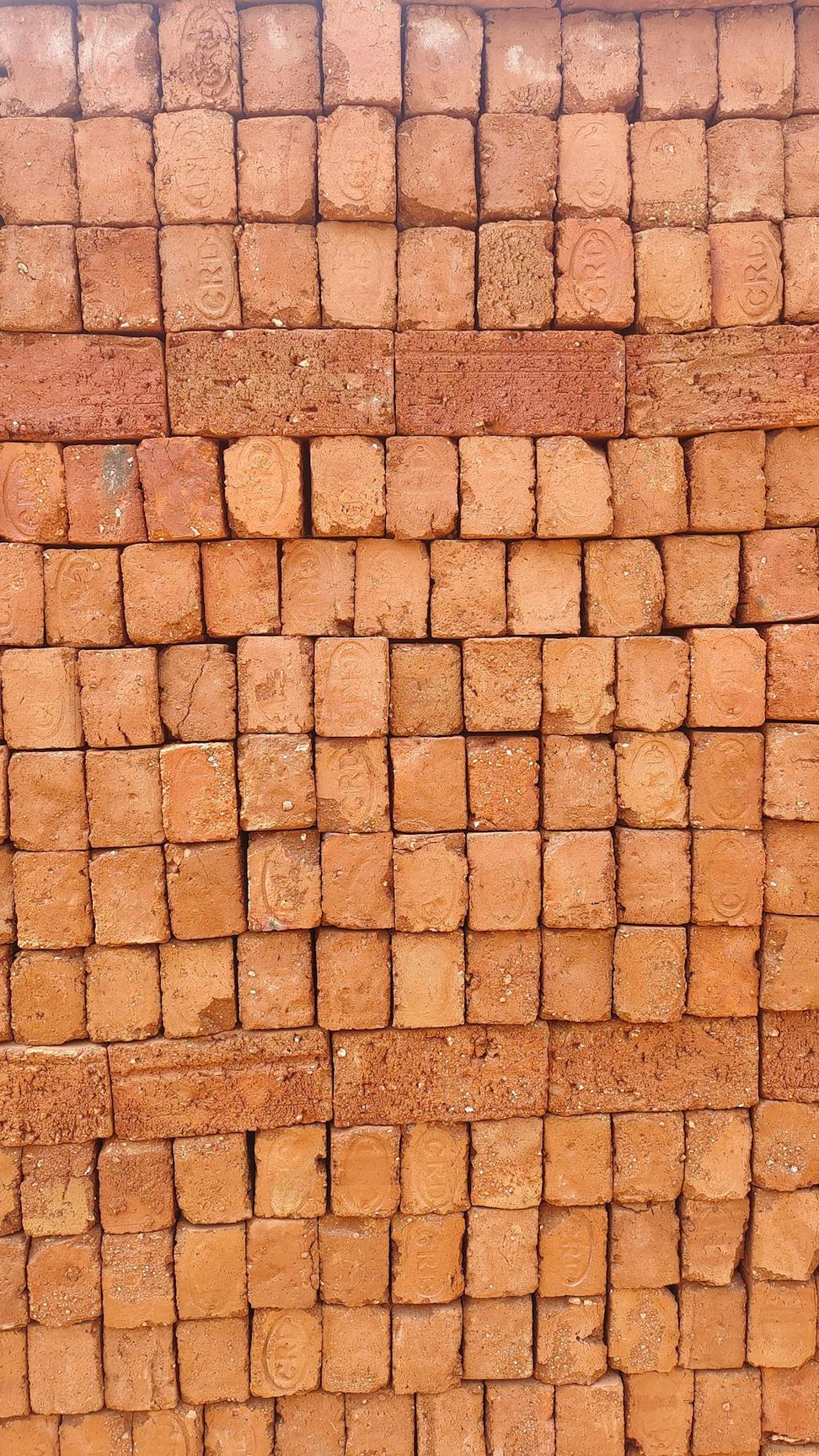

Painstaking brick restoration

New steel supports for the added floor

Completed & Occupied (October 2023)

Ground floor retail spaces filled up within weeks - coffee roaster, bike shop, and a little art gallery. Upper floors are office space for tech startups and creative agencies. The building has this energy now that's hard to describe. Old and new working together instead of fighting each other. That's what adaptive reuse should be.

Office space with original brick and new glazing

Ground floor retail maintaining heritage character

"I'll be honest - at first I thought the heritage restrictions were gonna kill the project financially. But Onyx Thor Valquint showed us how preserving the original character could actually be a selling point. The building's fully leased now and tenants are paying premium rates because of the unique spaces we created. They made the numbers work without compromising the design."

- David Chen, Westview Development Corp

Project Metrics

18,500

Square Feet

75%

Original Material Retained

LEED Gold

Certification Achieved

$8.9M

Total Investment

Squamish Modular Housing Pilot

Squamish, BC

Affordable housing that doesn't look like cheap housing - that was the brief. Working with the local housing authority to design a modular system that could be replicated but still feel like a real neighborhood. Plus we had to hit some aggressive budget and timeline targets.

From Concept to Community

Research & Design (Feb-June 2022)

We looked at modular housing projects across North America - the good, the bad, and the really ugly. Most failed because they prioritized speed over livability. Our approach was different: design a flexible module system that could be configured in different ways so each home felt unique. Also made sure every unit had proper outdoor space and decent natural light - basics that too many affordable projects skip.

Early design iterations and scale models

Working with the fabrication team on buildability

Prototype Testing (July-Oct 2022)

Built two full-scale prototypes to work out the kinks. Found issues with our initial window flashing details, discovered the HVAC units were louder than specs suggested, and realized we needed better acoustic separation between units. Way better to figure this stuff out before you're building 24 homes. The housing authority was cool about the extra time - they got that we were trying to do it right.

Module Fabrication & Site Assembly (Nov 2022-May 2024)

The modules were built in a factory in Kamloops - controlled environment meant way better quality control than traditional stick-building. Each unit took about three weeks in the factory, then two days to install on site. Watching them crane in a complete home was pretty wild. Site work took longer than the actual home installation - getting foundations perfect and all the utility hookups right was critical.

Module construction off-site

Installation day - always exciting

Site prep and foundation work

Move-In & Community Building (June 2024)

Families started moving in early summer. We stuck around for the first few months to deal with any punch list items and just see how people actually lived in the spaces. Got some good feedback that'll inform the next phase. The community garden we included was a hit - people were using it way more than we expected. That's the thing about good design - sometimes the simple stuff matters most.

Completed community with shared green space